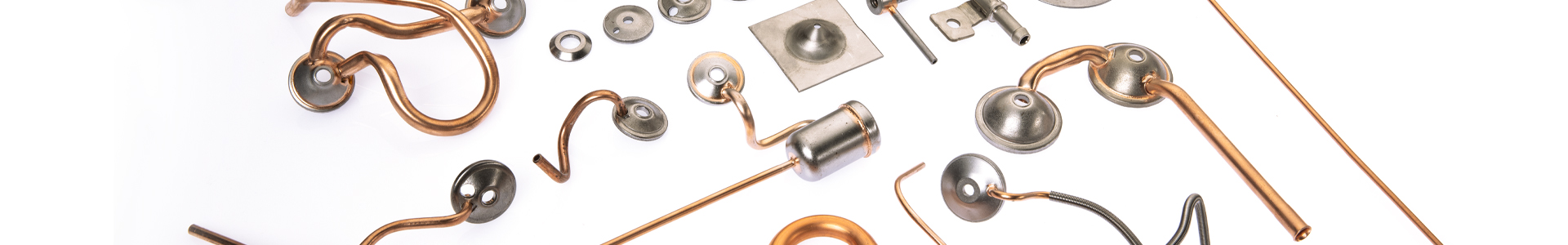

Pipe Bending & End Forming

Epta has extensive experience of complex pipe and profile bending in several different materials such as steel, stainless steel, aluminium, copper and brass. Our customers are world leaders in the white goods, automotive and engineering industries.

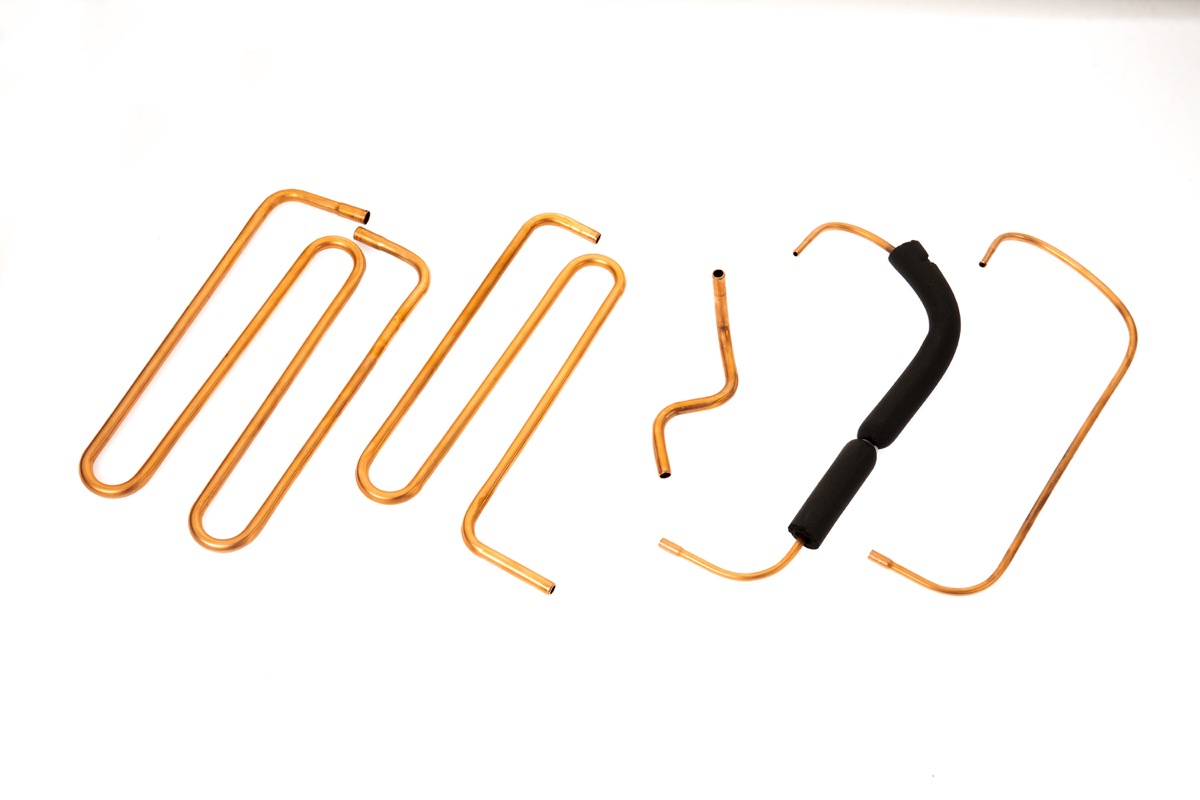

Thick And Thin Tube Bending

Our machines and equipments are capable of bending welded and seamless pipes and profiles made from various materials such as steel, stainless steel and aluminium. In addition to this, different shapes such as round, square hollow and even elliptical profiles and different treated such as coated or untreated pipes can be bent. Our CNC-controlled bending machines can handle pipes and profiles in the dimensions between 6–150 mm with or without mandrels and with a fixed radius or free of radius.

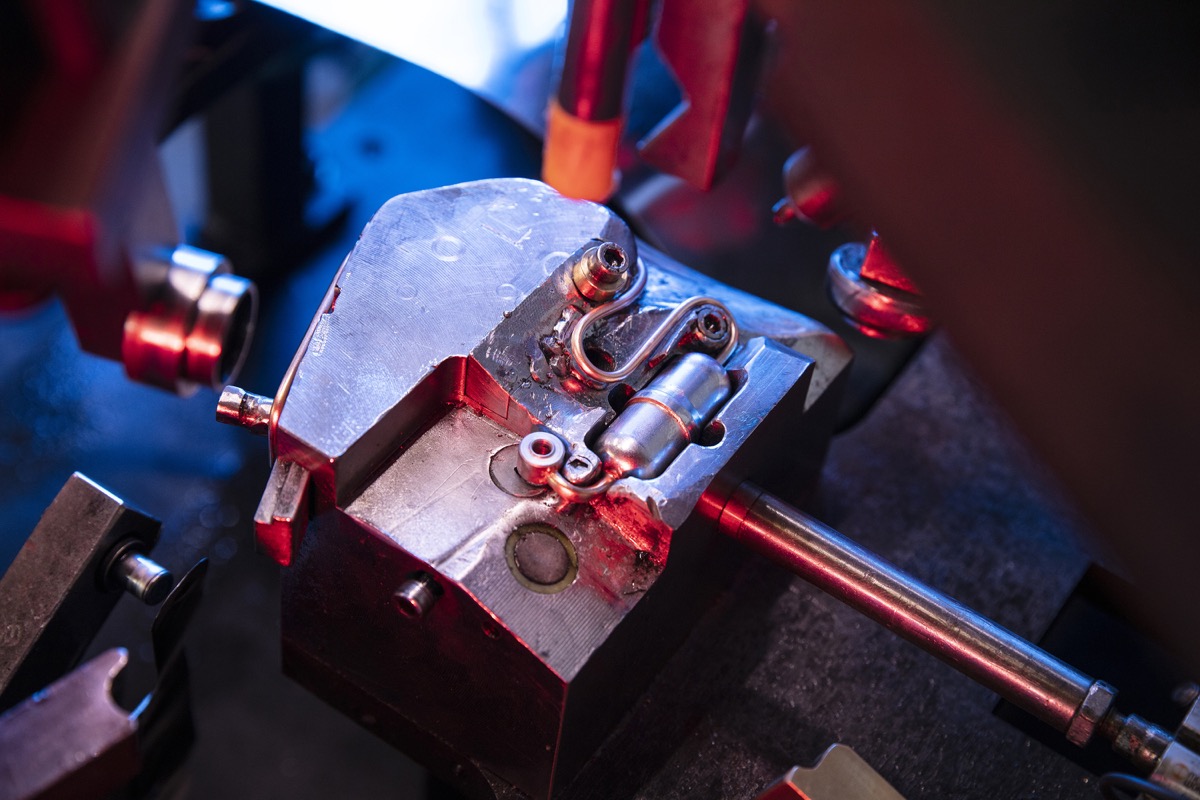

Automated Production Machines

In our production, we work with automated machines for pipe bending, section bending, end forming and making holes in the dimensions between 6–63 mm. To ensure the correctness of bending process in our machines, we use weld seam detection.

Our automated machines are also capable of performing studwelding for further assembly in required situations.

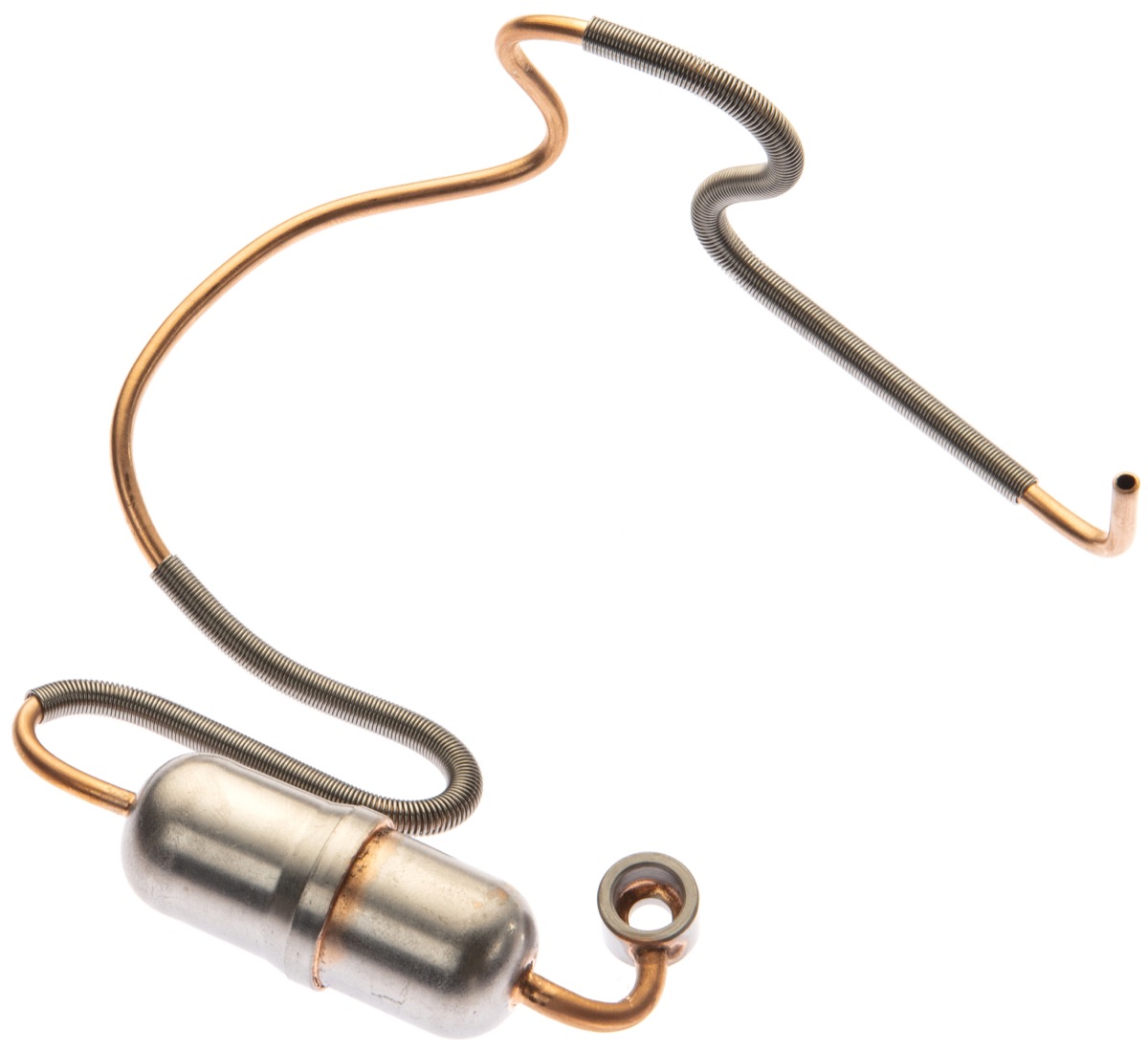

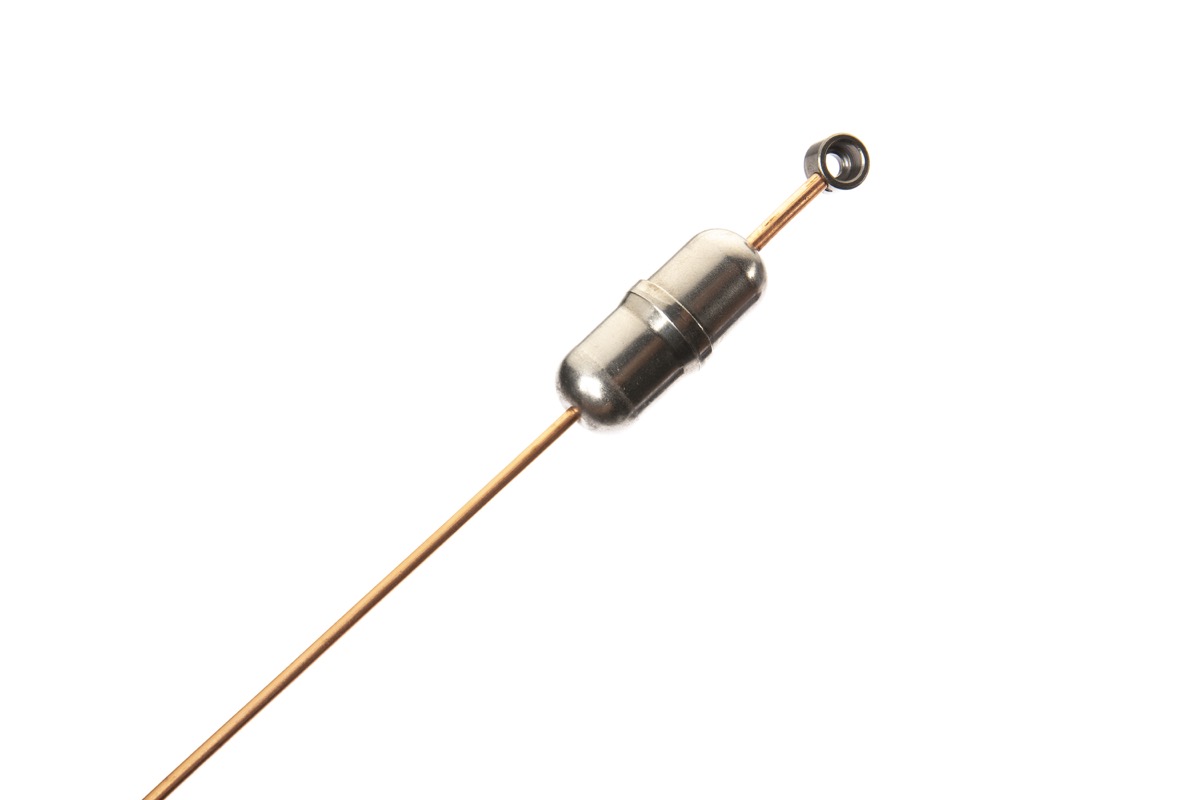

In most cases, end forming process is required before or after the pipe is bent.In those cases where end forming is not included in an automated machine, thiswill be performed as a separate operation. End forming is used for various reasons, such as hose stops for hose installation or as preparation before installation in various types of components etc.

End forming is a complex process that permits the installation of attachments first by shrinking the pipe so that after the attachment has been installed the pipe expands again.